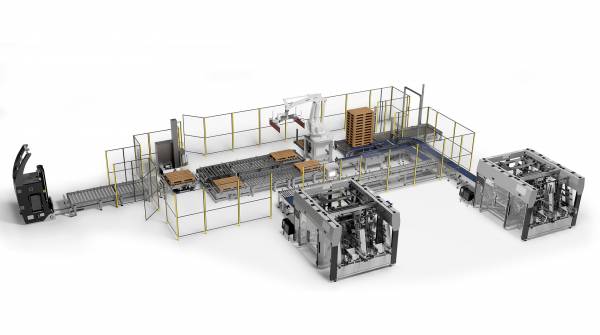

The All in One Solutions designed by Mad Automation combine two machines into a complete packaging line “from capsule to case” in a single frame.

This new type of machinery, fully scalable, can be composed of 4 main elements.

test

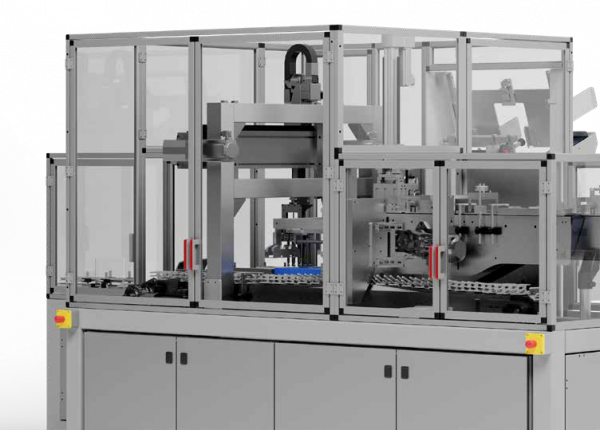

CARTONING MACHINE FOR SELF-PROTECTED CAPSULES.

The Cartoning Machine for self-protected capsules is Mad’s flexible and versatile solution to pack all types of compatible capsules currently available on the market: Nespresso, A Modo Mio, Lavazza blu, Dolce Gusto, Caffitaly, K-cup, Vertuo, etc...

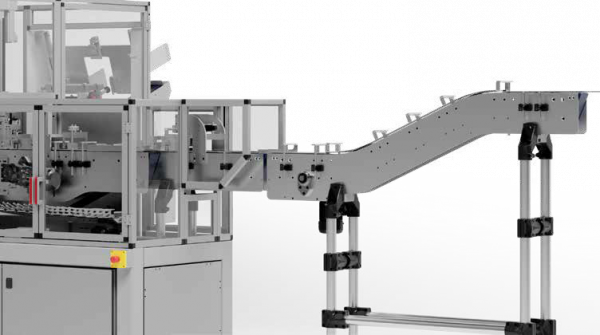

WEIGHT CONTROL SYSTEM

The Weight Control System is an essential tool to guarantee the quality of the final package and to ensure the respect of the correct product quantity in the case.

It is a high-performance device, integrated into the system, which suitable for a wide range of weights and sizes. It can also control the cases’ loading and the

non conforming product rejectionbefore they reach the marking and loading stations.

CASES MARKER

The all-in-one solution is equipped with a Case Marker easy to set up and operate. It is available either with laser or ink marking technology both in colors or black and white.

The print position is adjustable and settable on multiple lines. The marker can print all the data relevant to the productionlot, such as the production date, the expiration date, the identification number, etc... to grant total product traceability.

CASE PACKER

The Case Packer completes the all-in-one solution.

It can feature either a robotic arm or a picking head according to the customers’n requirements and it is able to handle a wide array of cases: Wrap Around, Display Tray + Lid, Display Tray, Ledge Tray and American Case.

The size changeover is fully automatic.

INPUT

INTERMEDIATE OUTPUT

OUTPUT