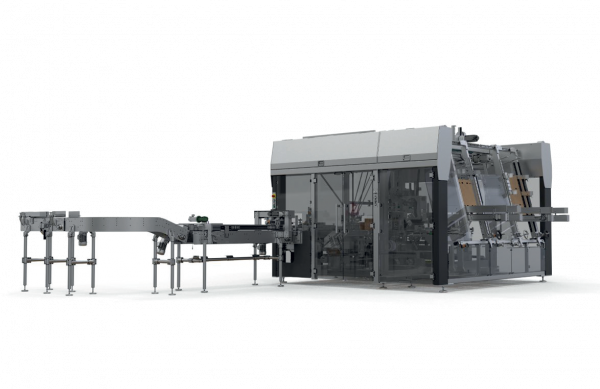

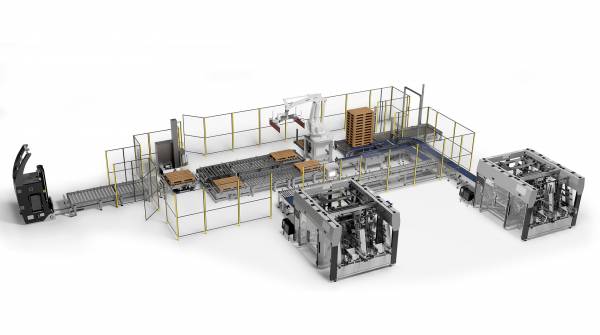

Mad Automation’s case packers are study and reliable machines designed to handle numerous types of packages.

They can feature standard or stainless steel components so to be suitable for all environmental conditions.

The solution for an accurate and versatile packaging.

Reliability

The machines are designed and built with sturdy materials and top quality standard electric and pneumatic components to work 24 hours a day, 7 days a week.

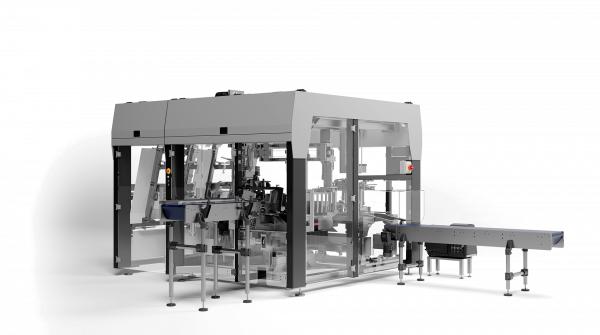

Automatic Size Changeover

The completely automated and easy-to-operate size changeover system grants an accurate and quick adjustment of the inner parts of the machine from the current product to the next.

Reduced Dimensions

Every single machine is designed, according to the clients’ specific needs, so to make the most of the space available. The integration of power switchboards into the top section of the machine optimizes the space, while facilitating the machinery positioning and accessibility from all sides.

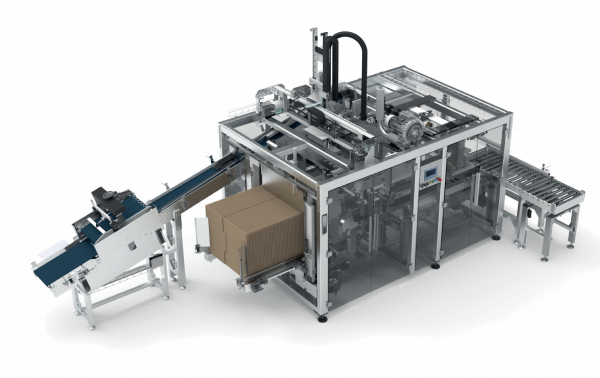

Respect For The Product

Throughout the case formation and packing process, the packs are always kept in correct position by rails and retractable holding flaps to prevent falls, bumps, breaks or micro damages. The sealing systems installed on the conveyors prevent product from warpage, optimizing the package size and allowing to recover up to 20% of usable space.

Easy Operation

The machines are fully accessible from all sides: this grants ease of use, reduces size changeover downtimes and simplifies setup and maintenance. By means of the touch screen HMI all data relevant to the speed and position of the the inner devices of the machine can be set an saved. They can also be retrieved and associated to a specific recipy.