The Brain 4.0 machine supervision software, is a scalable software package. By means of a centralized production process and logistics control it optimizes the Companies’ efficiency. Entirely developed in-house, its main feature is the possibility to be adapted to the customers’ machines and to be tailored to the customers’ production goals.

By using Brain 4.0 the customer will: fully control of the whole production process and avoid the lack of flexibility normally caused by software supplied by general software houses; make sure that machines, devices, databases and software all communicate in the same language thanks to a common “Brain”.

The Script Manager (SM) is Brain’s core. By means of powerful fully customizable functions it allows the creation and management of decisional logics to supervise all operations of a modern production plant. The SM can communicate with any system connected with the Plant Manager and to control it, such as the LGV fleet, the warehouse, the palletizers etc… The Script Manager also allows to create bespoke production planning rules.

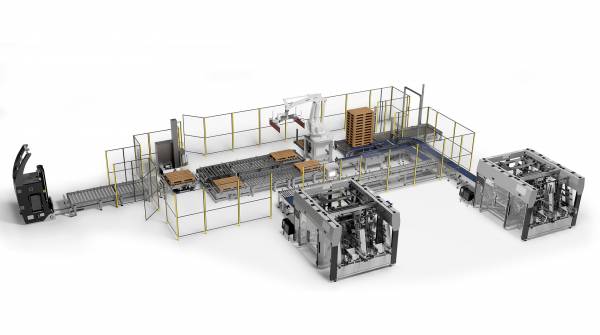

► Master Brain (MB) is the module coordinating all activities according to the Industry 4.0 logic. MB controls and executes all the processes within the production line.

► The Client Manager (CM) allows to create customized HMI interfaces. The Designer can create and modify OTA (over the air) all the plant’s interfaces be it control panels or statistics and administrative reports HMIs. All the HMIs can be defined in their operational functions and customized to every single operator.

► The Warehouse Management System (WMS) is specifically conceived to control the production facilities’ internal logistic processes. It is an integrated solution that allows to manage all automated and manual operations. The WMS controls multiple warehouses, it optimizes the products’ location and their transfer to a new spot to fine tune the LGVs’ flux.

► The Plant Manager (PM) is the integration, communication and control module for all the automatic systems composing the line. The module can communicate with both Mad Automation’s machinery and all other machines and devices. PM can also provide to the ERP or to third party software all the variables and the statuses of every single section of the line.

►The CT (Complete Traceability) module’s main purpose is to track down all products in the production line. The customer is thus able to control the products’ quality and conformity from the beginning down to the case and the pallet.

► ETU (Easy To Use) is an user friendly graphic interface allowing the operator to supervise the production line and to take timely actions in case of problems. ETU also grants the perfect operation of the remote service, by means of system alarms and an IP camera, Mad’s technicians get malfunction warnings from the system and are able to solve them in real time.