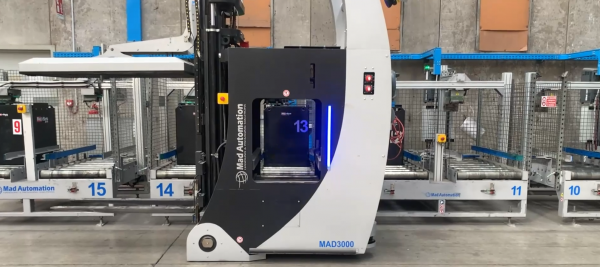

Mad Automation has developed a new generation of Laser Guided Vehicles for transporting materials such as pallets, containers, coils, etc. These vehicles can operate in any industrial sectors, and are particularly suitable for situations where the environmental

conditions are not safe for operators.

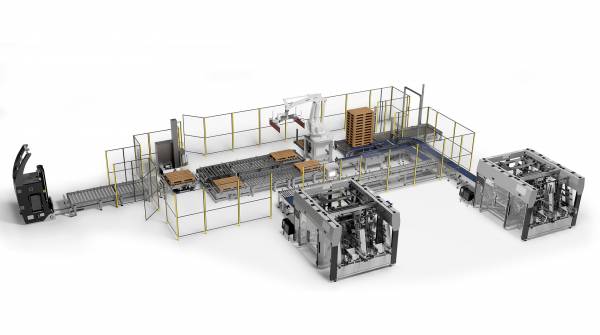

An automatic handling of internal logistics is also required when the goods are tracked by a software. The system allows to optimize loading and unloading operations to and from the warehouse and facilitates point-to-point transportation, even in chainmode operations.

LGV Shuttles

High-Tech Innovation

The material transport system with Laser Guided Vehicles by Mad Automation, is designed to meet the technological and the productivity needs of the customer, especially for 24h work shifts, and can also be semalessly integrated with existing systems.

Easy to Find Spare Parts

Mad’S vehicles and the entire system are made with electronic and mechanical components available on the market. This is a great advantage for end customers who can have their LGVs serviced by their personnel.

In House Software Development

The management and navigation software is developed entirely by Mad’s engineers in order to keep the know-how and to be able to adapt it to the needs of the most demanding customers.

Versatility and Sturdness

The vehicles are designed to work 24 hours a day, ensuring extreme reliability over the years. Mad’S LGV Shuttles can be completely reprogrammed in case of even radical modifications in the tasks to be performed thus resulting in a great investment.

Laser Guide Navigation

The total absence of ground infrastructure ensures maximum flexibility and freedom of movement, it also allows to modify or add routes at any time, just with the help of Mad’s PC software (CAD for routes creation).